Cable, rope, pipe winder

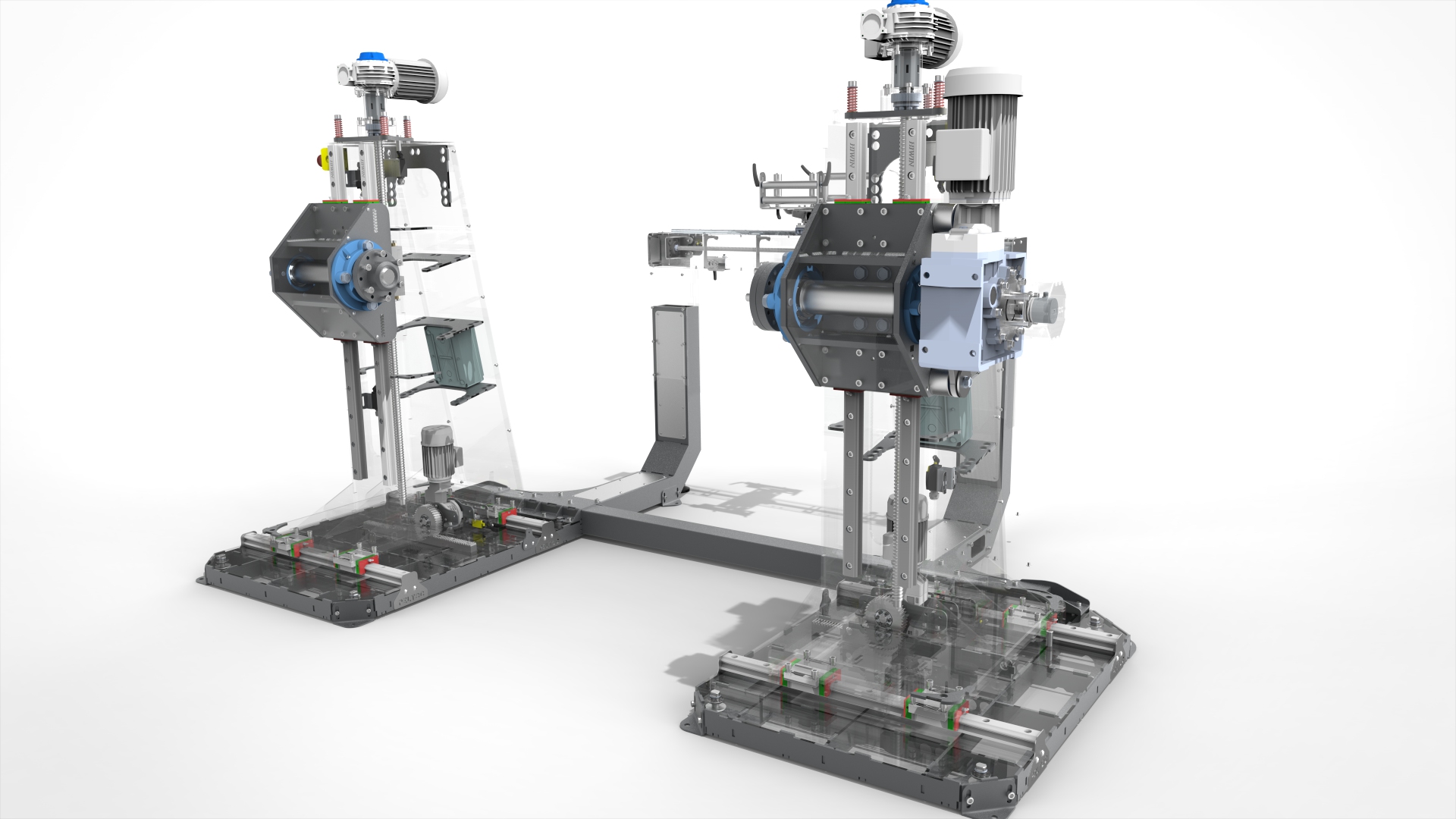

The PELTOC winding machine for pipes and cables has been developed based on over 10 years of experience in designing pipe and hose winding solutions. The device combines a reliable, simple, and robust design with solutions proven over the years. The winding machine uses only the most reliable components, ensuring minimal wear, low maintenance needs, and energy efficiency — extending the equipment’s lifetime and guaranteeing consistent performance. Our winder can be used for winding on various production lines, making it an ideal solution for many pipe and cable manufacturers worldwide.

Why choose our winding machine?

The PELTOC WIND 2400 winder is designed for maximum flexibility and ease of use. The machine does not require integration or configuration with an existing production line. No complex installation is needed: simply plug it into a 16A socket, and the machine is ready to use. This makes it the ideal winding machine for companies seeking versatile, efficient, reliable, and robust winding, saving time, reducing setup complexity, and ensuring smooth production.

Main advantages and futures

Adjustable Winding Torque and Speed

The winding torque and speed are independently adjustable via a special frequency converter, ensuring optimal performance for different products and materials.

|

Torque control: This helps maintain consistent product quality and improves drum winding precision. |

Speed control: This also allows faster winding from the accumulator/floor after a drum change, ensuring a quick return to normal production speed. |

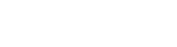

Accurate and robust Traverser

The traversing frame is built from stainless steel to resist corrosion caused by water from the cooling tank during production.

Features:

-

Smooth and precise movement controlled by a servo motor and intelligent logic

-

Convenient edge controls for position adjustment during operation or setup

-

Adjustable travers frame height to ensure better result

-

Adjustable Winding Width (Shown with blue circles in the image)

The winding width can be adjusted using sensors located at both edges of the traversing frame. The sensors are set according to the selected drum width.

User-Friendly 7” Industrial Touchscreen & Operator panel

-

Simple main menu: Only two key parameters need to be entered on product change — pipe diameter and drum edge delay. All other machine control during operation is carried out via the movable operator panel.

-

Advanced menu: Access a wide range of machine settings for fine-tuning and custom setups for each client.

-

Durable screen: Scratch-resistant, high-hardness glass with IP65 protection ensures a long lifespan.

The main control of the winding machine is operated via a movable operator panel, which working range can be used along the front and rear sides of the winder. This allows for easy and quick drum changes and setup adjustments.

The operator panel provides control over the following functions:

-

Starting and stopping the winder

-

Moving the drum lifting posts together/apart and up/down

-

Adjusting winding speed and tension

-

Controlling the traversing unit position (with the option to make adjustments during operation)

-

An additional button: “Automatic Drum Release”

Automatic Drum Release is solution: when drum is full and winding is complete and the product is wrapped or fixed, simply press the Automatic Release button on the control panel. In this case machine automatically lowers the drum to the floor and moves both towers away — no need to hold buttons or wait. (It will also avoid floor and drum damages in wrong use)

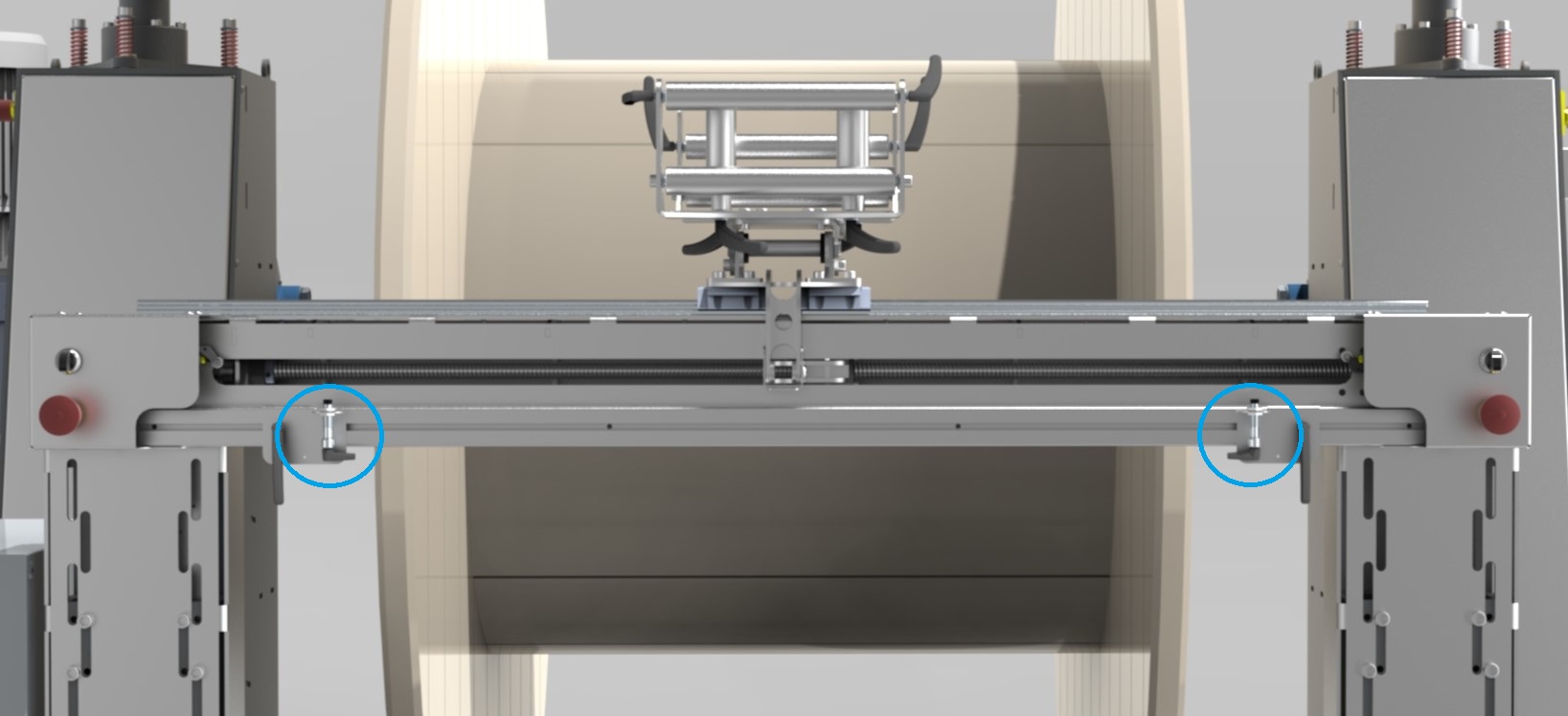

Main Drive System

A main motor with bevel gearbox allows for manual drum rotation by hand, ensures smoother winding, and reduces gearbox stress during sudden stops.

Protected Components

Critical components — such as encoders, wiring, servo motors, end switches, and sensors — are securely integrated within the frame to prevent external damage and extend service life.

Transport Beams – easy to move, easy to use.

The included transport beams allow the machine to be moved quickly and safely with a pallet jack. If needed, it can be used fastly on different production lines depending on product orders, or even for product rewinding.

Technical Specifications

| Specification | Value |

|---|---|

| Producer: | PELTOC |

| Model: | WIND 2400 |

| Max drum rotation speed: | 1–17 RPM (optionally up to 200 RPM) |

| Max winding speed: | Up to 200 m/min (depends on drum diameter) |

| Max drum weight (full load): | 1,700 kg (optionally up to 4,000 kg) |

| Max drum diameter (outside): | 2,400 mm (optionally up to 4,000 mm) |

| Min drum diameter (lift from floor): | 1,000 mm (optionally from 600 mm) |

| Max drum width: | 1,250 mm (optionally up to 1,600 mm) |

| Min drum width: | 730 mm (optionally down to 300 mm with spacers) |

| Drum center hole diameter: | 105 mm (customizable, Later also easily changeable) |

| Compressed air: | Not required |

| Power supply: | 400V / 50Hz / 3-phase (16A plug) |

| Machine weight: | 1,445 kg |

| Dimensions (L × W × H): | 2250 × 3100 × 1882 mm |

|

Maximum winding Speed depends from Drum Diameter

|

Customizable solutions are always possible — the winding machine can be adapted to meet the specific needs of each client.